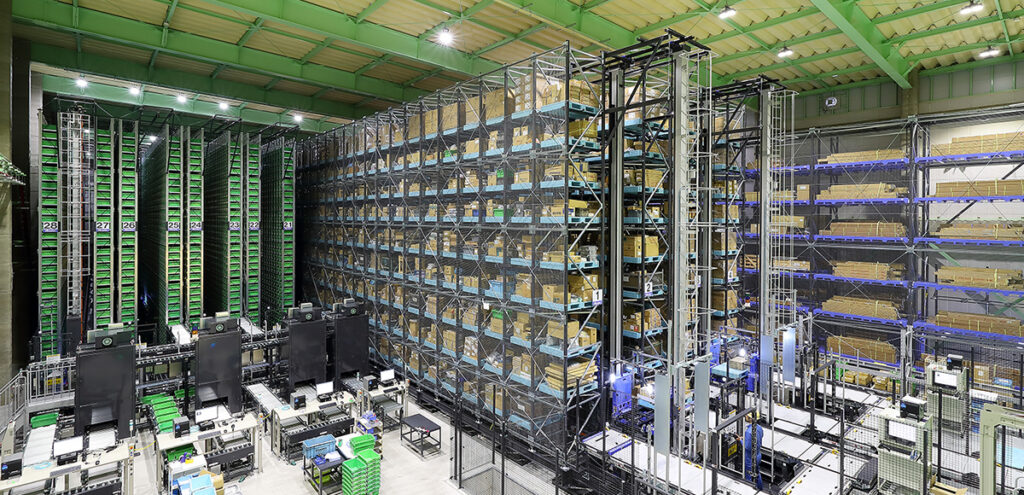

3D robot warehousing system ALPHABOT

The robot carriage “BOT” performs all of storage, transport, sorting and picking in an integrated G2P (Goods To Person) robot warehousing system.

Since the “BOT” can access all storage racks/picking stations, picking by order can be performed with one system.

Simple system

The robot carriage “BOT” can move in horizontal and vertical directions by itself.

Thus, it excels in maintainability and redundancy because there is no need for conveyors, elevating lifts, and other equipment to bring packages to workers.

Excellent expandability

Storage racks, work stations, etc., which are designed in units, can be easily expanded in combination with robot carriages according to the capacity required.

Related Information

-

AS/RS

-

Shuttle system Uni-SHUTTLE HP

-

Case transport and sorting carriage system SHUTTLINER

-

Cold chain solutions

-

Software

-

Camera/sensing system

-

Support system

-

Smart solutions

-

Automobile parts

-

Electronic and precision machinery

-

E-commerce

-

Distribution of medical supplies and miscellaneous items for daily use

-

Food distribution

![Logistics & Automation[MURATEC,MURATA MACHINERY, LTD.]](https://logistics.muratec.net/la/wp-content/uploads/2021/08/common_logo.gif)