Case studies

Pharmaceutical and Medical Device Distribution

Product

3D robot warehousing system ALPHABOT

Shuttle system Uni-SHUTTLE HP

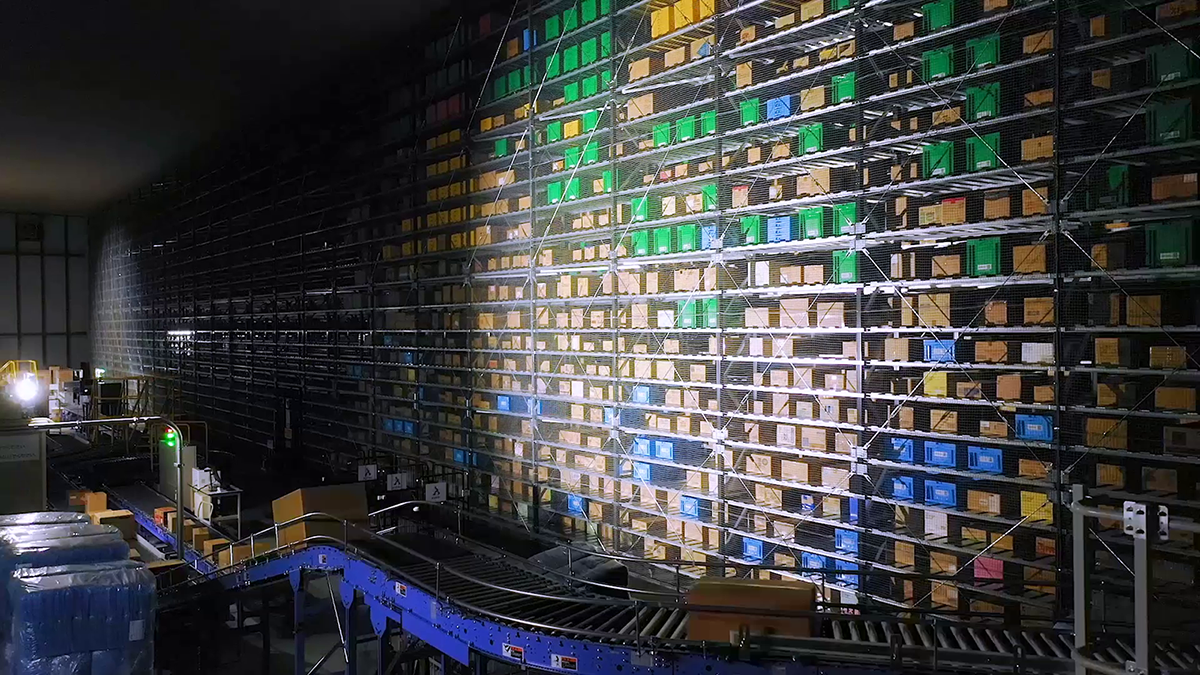

E-commerce

Product

AS/RS

Automated transportation & sorting vehicle RTN-X

Shuttle system Uni-SHUTTLE HP

Case transport and sorting carriage system SHUTTLINER

Retailer

Product

Shuttle system Uni-SHUTTLE HP

Case transport and sorting carriage system SHUTTLINER

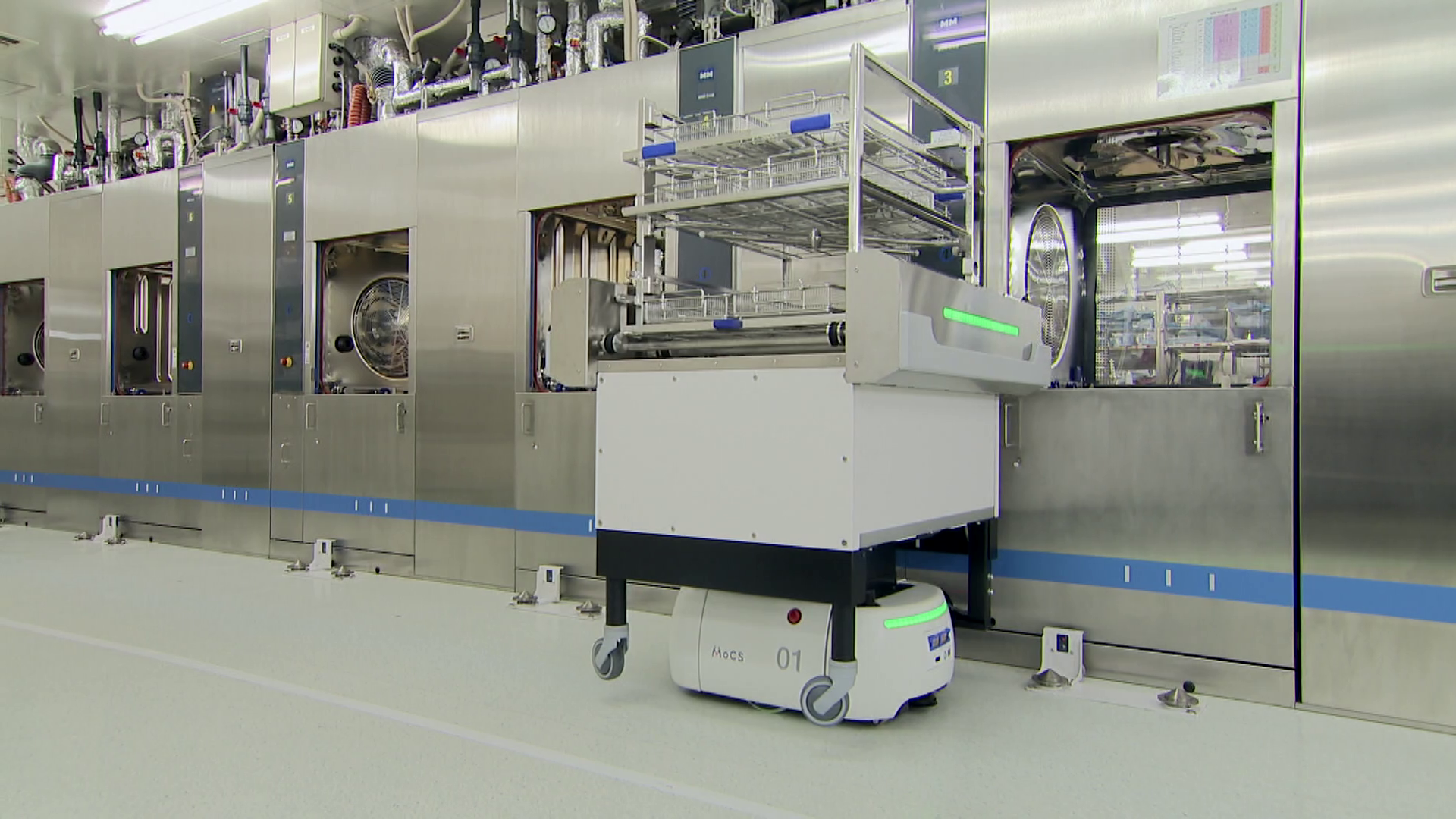

Hospital

Product

In-hospital transportation systems

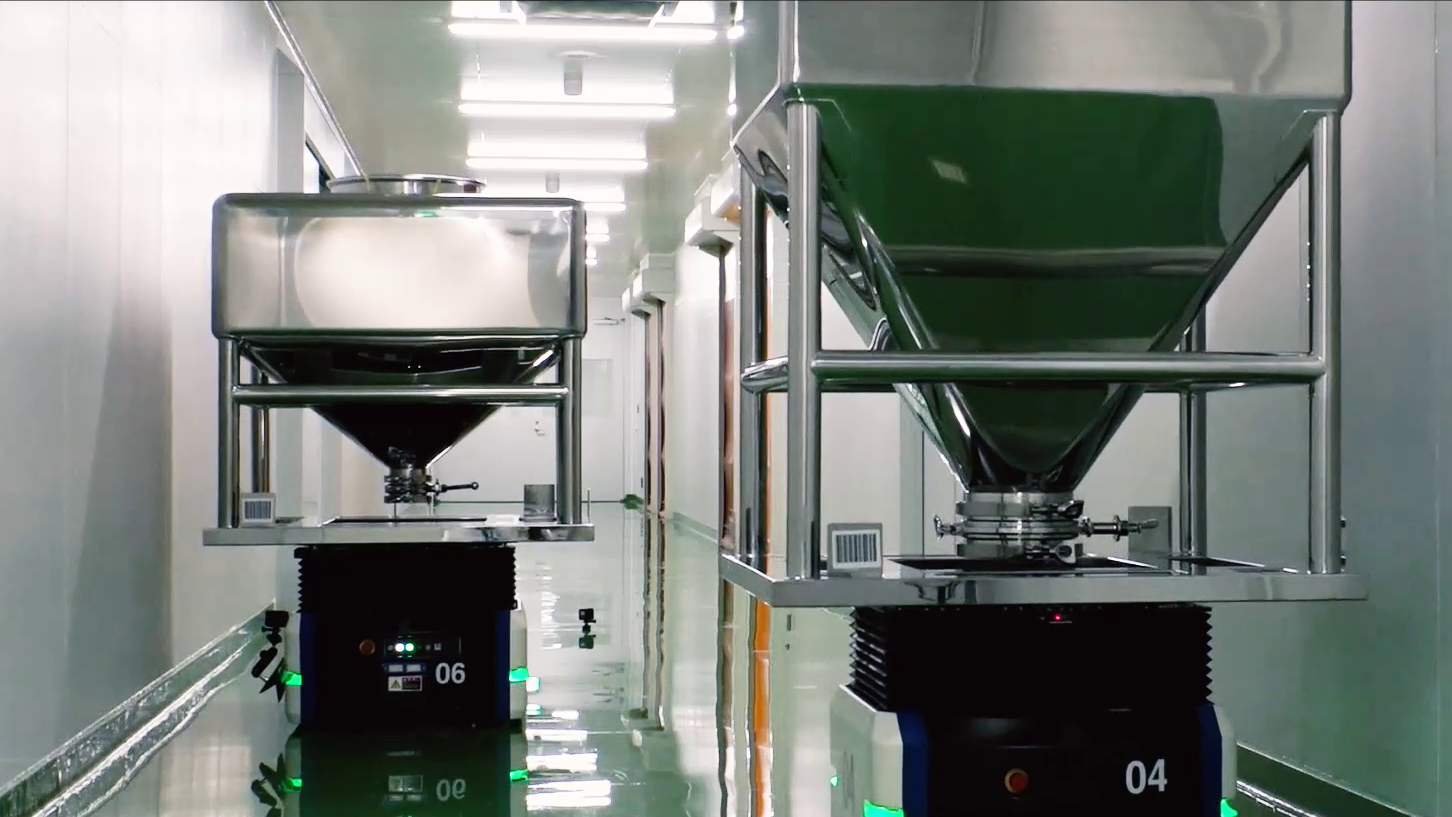

Pharmaceutical manufacture

Product

AS/RS

Smart AGV Premex XIO

Retailer

Product

3D robot warehousing system ALPHABOT

Whisky Distillery

Product

AS/RS

Machine manufacture

Product

AS/RS

Automated forklift Premex SLX

AGV Premex

Cosmetics manufacture

Product

AS/RS

Automated transportation & sorting vehicle RTN-X

Shuttle system Uni-SHUTTLE HP

Food distribution (Cold chain)

Product

AS/RS

Shuttle system Uni-SHUTTLE HP

Food manufacture

Product

AS/RS

Automated transportation & sorting vehicle RTN-X

Stationery manufacture

Product

AS/RS

AGV Premex

3PL (Cold chain)

Product

AS/RS

Automated transportation & sorting vehicle RTN-X

Distribution of medical supplies and miscellaneous items for daily use

Product

AS/RS

Food distribution (Cold chain)

Product

AS/RS

3PL

Product

AS/RS

Beverage manufacture

Product

Shuttle system Uni-SHUTTLE HP

Pharmaceutical manufacture

Product

AS/RS

Automated transportation & sorting vehicle RTN-X

Food distribution (Cold chain)

Product

AS/RS

Food manufacture

Product

Automated forklift Premex SLX

Food manufacture

Product

AS/RS

Automated transportation & sorting vehicle RTN-X

Shuttle system Uni-SHUTTLE HP

Automobile parts

Product

AS/RS

Automated transportation & sorting vehicle RTN-X

Food distribution (Cold chain)

Product

AS/RS

Automated transportation & sorting vehicle RTN-X

Libraries

Product

AS/RS

Electronic and precision machinery

Product

AS/RS

Retailer

Product

Crossbelt sorter

Food distribution

Product

Pharmaceutical and Medical Device Distribution

A major distribution center for a medical and scientific device wholesale business that helps support the medical and research fields. The company utilizes a GTP system which uses ALPHABOT to automate everything from storage to picking, and Uni-SHUTTLE for sorting and shipping to improve efficiency and reduce workload burdens on employees.

E-commerce

A leading B2B delivery sales company that provides one-stop delivery services on a next-day delivery basis to customers throughout Japan for everything from office supplies and daily sundries to tools required for manufacturing fields and general medical products and pharmaceuticals. The company uses an original and unique distribution system that combines automated storage and retrieval systems with high-speed sorters, vertical transport systems, and shuttle systems to construct a mode that allows faster and more reliable deliveries.

Retailer

A supermarket distribution center. It is equipped with chilled center functions for handling perishable foods, daily deliveries, delicatessen products, etc., as well as grocery center functions for handling general food products, alcoholic beverages, home goods, and snacks. The center has introduced a sequential shuttle system, which ships out products by store and category, and a GTP system, which combines Uni-SHUTTLE and SHUTTLINER products to improve distribution efficiency.

Hospital

Here is an example of using the MoCS hospital transport system as part of a surgical instrument washing line. MoCS automates loading used instruments and removing cleaned equipment in and out of the washing machine. This frees workers from heavy labor for more critical tasks.

Product

In-hospital transportation systems

Pharmaceutical manufacture

Examples of AGVs being used in pharmaceutical production plants. The system prevents cross-contamination and human error by storing materials, raw materials, and intermediate products in AS/RS warehouses and then transporting them in and out of the warehouses and between processes using AGVs.

Retailer

A key distribution facility for a top domestic sports retail brand. The G2P system, which automates everything from storage to sorting by ALPHABOT, significantly decreases the number of walking tasks, reduces man-hours, and lessens the workload.

Whisky Distillery

A liquor storage warehouse for unblended malt whisky was established in response to a global increase in popularity amid a whisky supply shortage. The introduction of an AS/RS made it possible to achieve high-density storage of casks while also allowing for safe and highly efficient sampling to be carried out.

Product

AS/RSMachine manufacture

A machinery manufacturer parts processing line. By linking and integrating the AS/RS, transport, and manufacturing management systems, supply tools and materials are automatically supplied according to processing timing. This creates a manufacturing line with seamlessly connected processes.

Cosmetics manufacture

A distribution center for a top cosmetics manufacturer. The system aims to respond to labor shortages and increased physical distribution challenges through automation. This flagship manufacturing and distribution location exists on the same site as the company's factory, and Muratec's storage and transport systems are utilized in both the factory and distribution center.

Food distribution (Cold chain)

A core distribution center in the Nagoya megalopolis area of a comprehensive food product wholesaler supporting the region's food infrastructure. This center has introduced a Mini-Load AS/RS and a Uni-SHUTTLE HP, both compatible with -25℃ frozen environments, to meet the increasing demand in the frozen foods market.

Food manufacture

A leading domestic confectionary manufacturer. The company introduced a new product storage and retrieval system built around an AS/RS for a core factory for some of the company's popular long-selling products. The system uses innovative solutions and ideas to resolve issues, such as utilizing sheet pallets in areas with limited space.

Stationery manufacture

A manufacturing plant for a comprehensive stationery manufacturer with popular global products. Muratec designed and developed a picking system customized for the worksite's operations with the customer to automate the supply of materials to the manufacturing line.

3PL (Cold chain)

A comprehensive logistics company that conducts a wide range of distribution-related operations, including shipping, warehousing, customs clearance, and more. In response to an increase in the quantity of frozen food products being handled, the company constructed a freezer AS/RS. This allowed for automation of the warehouse stocking and retrieval operations in freezer environments previously carried out by manual labor, helping to combat labor shortages and improve working environments.

Distribution of medical supplies and miscellaneous items for daily use

A Taiwanese housing material wholesale business. In their distribution warehouse, the company introduced a G2P (Goods-to-Person) system utilizing a gantry-type AS/RS to improve operation efficiency, especially for picking tasks.

Product

AS/RSFood distribution (Cold chain)

A distribution center for a general food product trading company that handles distribution for school lunch suppliers in the Tokyo metropolitan area and food services, which mainly supply restaurants. The company utilizes a freezer bucket AS/RS as a storage and picking system for high variety, low volume frozen food products to fully automate work carried out in freezer environments.

Product

AS/RS3PL

A distribution center for automotive parts. The center is vital in delivering parts on time to automotive manufacturers who manufacture in a just-in-time process. The introduction of AS/RS improved space efficiency and picking work efficiency and alleviated labor shortage issues.

Product

AS/RSBeverage manufacture

A distribution center for a major beverage producer. Improving the efficiency of operations in the distribution site became an issue to adapt to shifting market needs for high variety, small lot production. Introducing the Uni-SHUTTLE HP has improved picking and made sorting more efficient.

Product

Shuttle system Uni-SHUTTLE HPPharmaceutical manufacture

A generic pharmaceuticals manufacturer. The company introduced automation technologies to achieve large-scale production. The company improved production efficiency by utilizing an AS/RS for storing raw materials and products and an intermediate product AS/RS to supply work-in-process product containers to each process.

Food distribution (Cold chain)

A western confectionary producer and seller which operates franchise shops throughout Japan. This facility is a relay center that stores products and distributes them to individual shops. The center introduced a freezer AS/RS equipped with a seismic isolation system and a remote video monitoring system to ensure supply can continue even in emergencies.

Product

AS/RSFood manufacture

A production plant for a confectionary manufacturer. The company has aggressively introduced automation technologies to improve production process efficiency and resolve labor shortage issues. The company achieved a flexible building and production equipment layout using the SLX automated forklift system, which features multi-drive and SLAM navigation.

Product

Automated forklift Premex SLXFood manufacture

A factory-attached distribution center for a dairy products producer. The company constructed a system that seamlessly connects production and warehouse management systems, delivers raw materials from the distribution center to the factory according to the progress of production, and then delivers completed products to the distribution center.

Automobile parts

A United States automotive parts manufacturer located in the state of Ohio. The company introduced a mini-load AS/RS system to store box pallets to resolve issues with insufficient storage for pre-shipping products on the factory site and improve shipping efficiency.

Food distribution (Cold chain)

A major distribution center for a comprehensive food product wholesaler equipped with logistics and distribution functions, three temperature ranges, and all categories of products, including dry, chilled, and frozen. It also features an area for vegetables shipped directly from production sites. By introducing an AS/RS system, the center improved storage efficiency and shipping and sorting work efficiency.

Libraries

A university library in the state of Virginia in the United States. The library houses a collection of approximately 420,000 books. The library utilizes specialized transfer devices for high-density storage of books in specialized cases in an AS/RS.

Product

AS/RSElectronic and precision machinery

A leading global manufacturer of ultra-compact electronic circuit boards. The company introduced an AS/RS for pre-assembly part collection processes. A G2P system was constructed to retrieve part cases from the AS/RS and transport them to picking stations. This system made it possible to reduce the number of work processes by approximately 75%.

Product

AS/RSRetailer

A distribution center for major domestic furniture sales shops. The center introduced crossbelt sorters to automate product sorting. This made it possible to reduce by approximately one-third the time required for the work to be carried out manually, contributing to significant reductions in personnel expenses and other costs.

Product

Crossbelt sorterFood distribution

A fresh food processing center that carries out everything from processing of prepared foods and quality meats to supply to supermarket locations. The center utilizes an AS/RS for crate storage. All stages, from crate washing to storage and supply to PC, are automated to achieve a system that requires no manual labor.

Product

Products

3D robot warehousing system ALPHABOT

Shuttle system Uni-SHUTTLE HP

AS/RS

AS/RS

Smart AGV Premex XIO

Automated forklift Premex SLX

Case transport and sorting carriage system SHUTTLINER

Overhead transportation system SKY RAV

Muratec E-LOGICS

The robot carriage “BOT” performs all of storage, transport, sorting and picking in an integrated G2P (Goods To Person) robot warehousing system.

Since the “BOT” can access all storage racks/picking stations, picking by order can be performed with one system.

The shuttle type AS/RS combines flexible storage and sophisticated transport/sorting functions. With utilization of high storage and retrieval capabilities, group retrieval and retrieval in permutations and in order are realized.

As storage, transport, and sorting functions are integrated, transport to processes and replenishment for picking are automatically performed while storage and retrieval as well as inventory are managed by WMS (warehouse management system). This is an automation solution that makes the flow of things smooth at distribution centers and production sites through integration with information.

製品

As storage, transport, and sorting functions are integrated, transport to processes and replenishment for picking are automatically performed while storage and retrieval as well as inventory are managed by WMS (warehouse management system). This is an automation solution that makes the flow of things smooth at distribution centers and production sites through integration with information.

製品

Flexible transport systems that dynamically respond to various market changes are realized. Conveyors and other fixed equipment are reduced by compact-bodied lifter transfer which is capable of direct transfer from AS/RS cranes and production equipment.

The forklift type AGV can be easily introduced in existing warehouses, facilitating layout changes. The adoption of the SLAM guidance method can reduce incidental work, including laser reflectors and magnetic spots.

Operating multiple linear-motor-driven carriages, the sophisticated case transport and sorting system realizes the transport function of conveyors and the sorting function of sorters simultaneously.

The effective utilization of ceiling space enables transport at the shortest distance and flexible layout.

“Muratec E-LOGICS” is an integrated brand of logistics, software, and solutions provided by Muratec in order to realize logistics infrastructure in the coming age: connected logistics. We provide one-stop solutions, where every piece of information from daily operations that change from moment to moment, management and maintenance, to emergency responses at logistics sites dynamically responds to various systems within supply chains, including external distribution centers, sales and production, and transportation and delivery, with full-turnkey from WMS to WCS, equipment control, through sensing that visualizes sites.

![Logistics & Automation[MURATEC,MURATA MACHINERY, LTD.]](https://logistics.muratec.net/la/wp-content/uploads/2021/08/common_logo.gif)